4.5.19 – SSI

Here are some critical components dealers and integrators should always keep in mind when designing an effective smoke and heat detection system

Aspirating smoke detection (ASD) systems actively draw in air from the environment and may notify building staff of a potential fire in very early stages.

From historic buildings to critical infrastructure to local hospitals, dealers and integrators are tasked every day with creating fire/life-safety system solutions in a wide variety of environments.

While there isn’t a one-size-fits-all solution, there are critical components dealers and integrators should always keep in mind when designing an effective smoke and heat detection system for their customers.

Stay Updated on Latest Code

Code compliance is essential to an effective smoke and heat detection system. As building materials continue to shift toward engineered materials and synthetics manufacturers and dealers will need to have a regular conversation about the latest codes and the compliant products available to meet those changes.

Starting in May 2020, new tests will be required for listing of devices to the UL 268, 7th edition, standard for smoke detectors. The new tests fall into one of two categories. The first is the addition of new polyurethane (PU) foam fire tests and the second is the addition of a cooking nuisance resistance test.

The nature of building materials and furnishings have evolved through the decades. Many materials used in the 1970s and prior were made from natural resources such as wool, cotton, silk and wood.

But in the past 20 years there has been a significant shift toward engineered materials and synthetics, like polyurethane foam. These materials have shown they can burn hotter and faster than natural materials, and may produce higher levels of smoke.

Achieving greater sensitivity to smoke characteristics is critical because it ultimately impacts egress time, the amount of time occupants have to escape a fire. Separately, nuisance alarms (or false positives) are also being considered.

In response, the National Fire Protection Association (NFPA) added a new requirement in the 2013 edition of NFPA72 that requires all smoke alarms and detectors installed between 6- and 20-feet of a stationary cooking appliance to be listed for resistance to normal cooking activities. In response to this change, the UL standards added a new cooking nuisance smoke test.

Understanding the Environment

Dealers and integrators should be as detailed as possible in conversations with customers to truly understand the intended use of the space and the activities happening within. This helps to ensure the area is properly covered with the right technology and take any of the customers’ unique design aesthetic requests into account.

While safety is a top concern for all customers, they may also want to maintain a certain design style or accommodate a specific environmental condition. Challenging environments, such as hotel bedrooms or dressing areas near bathrooms with shower steam, may suit multicriteria spot detectors.

These detectors use a number of sensors to determine if a fire is real or not. For example, traditional beam smoke detectors are often the detector of choice for large, open spaces such as malls because they can cover an area that would require a dozen or more spot detectors.

However, large open areas that experience building movement such as warehouses may be better suited to the new optical imaging beam detector technology or aspirating smoke detection (ASD) that may more easily accommodate these conditions.

Ensure Futureproofing

Dealers and integrators should be aware of their customers’ plans for their buildings such as any potential changes in facility usage and renovations that could affect the system once installed. A flexible solution where current and new additions can work together will allow for dealers to always make sure they’re meeting their customer’s needs.

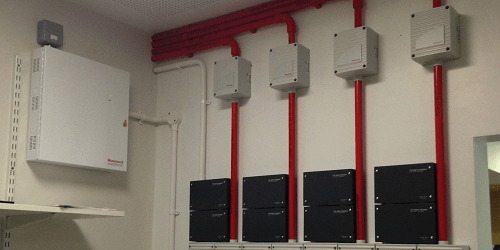

For example, innovations in aspirating smoke detection (ASD) technology have created flexible and highly reliable smoke-detection solutions that can detect the early presence of fire, while reducing the cost of nuisance alarms.

Integration and connectivity is becoming increasingly important to business owners, and the reliable, flexible design of ASD allows the technology to be integrated with widely used fire panels currently in the industry, providing future-proof expandability for maximum flexibility.

Unlike traditional spot detectors, ASD systems actively draw in air from the environment and may notify building staff of a potential fire in very early stages to allow effective early response to reduce business interruption.

ASDs are increasingly used across a wide range of environments including transportation, logistics, education and manufacturing industries.

While meeting codes is always top of mind, it’s important for dealers and integrators to fully understand the operations and environment within a facility, and the customer’s vision for the future.

Providing highly effective smoke and heat detection systems requires full transparency with each individual customer and installing high quality solutions that can evolve alongside the facility if needed.

Jurgen Van Goethem is General Manager, Commercial and Enterprise Fire, at Honeywell.

.